Is Farm-Free Food the Future?

The end of agriculture draws nigh.

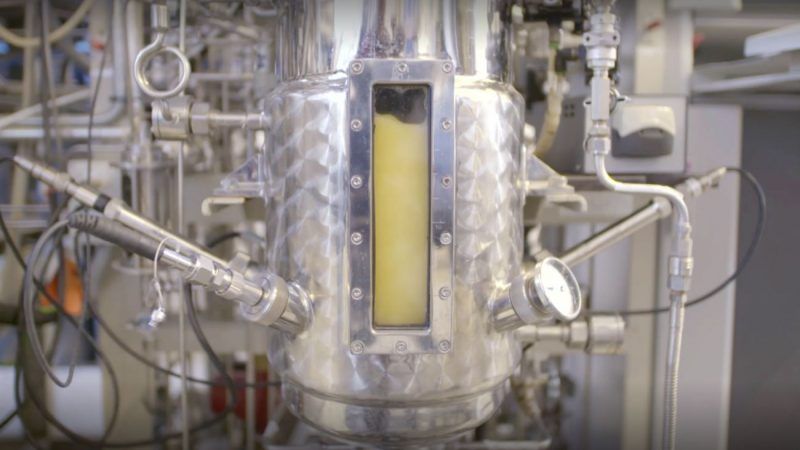

Factory farming may soon well mean something quite different than feedlot cattle and battery chickens. Entrepreneurs around the globe are seeking to replace conventional farming with shiny clean aluminum bioreactors that churn out tasty steaks, drumsticks, and flour. If this vision works out, the human footprint on the natural world will shrink dramatically since we use about one-third the world's land to produce food.

Recently, plant-based meats created by Impossible Foods and Beyond Meat have gained some traction in the marketplace. Both products have significantly less impact on the natural environment than does the equivalent beef product. For example, the carbon footprint of an Impossible Burger is "89 percent smaller than a burger made from a cow," according to one life-cycle analysis. It also "uses 87 percent less water than beef, uses 96 percent less land, and cuts water contamination by 92 percent." Another study found that a Beyond Beef burger "generates 90 percent less greenhouse gas emissions, requires 46 percent less energy, has >99 percent less impact on water scarcity and 93 percent less impact on land use than a 1⁄4 pound of U.S. beef." Of course, most of the ingredients for these products are still grown on farms.

Now comes the proposition that "ferming" in order to produce edible proteins and carbohydrates will displace most farming. Ferming is a portmanteau word combining fermenting with farming. "While arguments rage about plant-versus meat-based diets, new technologies will soon make them irrelevant," boldly asserts journalist George Monbiot over at The Guardian. Monbiot, who is promoting his new documentary Apocalypse Cow, explains that "before long, most of our food will come neither from animals nor plants, but from unicellular life."

Solar Foods in Finland functions as Monbiot's dawn herald of the brave new world of fermented foods. The company promotes itself as producing "food out of thin air." Solar Foods's fermenting microbes produce a high-protein powder, marketed as Solein, in bioreactors using carbon dioxide captured from the atmosphere and hydrogen generated using renewable electricity, along with added nutrients like sodium and potassium. Solein is 65 to 75 percent proteins and its amino acid composition is comparable to conventional sources like soybeans and beef. Consumers will not eat Solein flour directly. Instead, it will be a food ingredient replacing conventional proteins in almost any food product.

The company claims that fermenting one kilogram of Solein flour uses 500 times less water than producing a kilogram of beef and 100 times less than a kilogram of plant proteins. With respect to land use, Solein is 60 times more efficient than plants, and 1,000 times more so than beef. Taking post-farming afforestation into account (trees returning to abandoned cropland and pastures), producing Solein actually reduces atmospheric carbon dioxide concentrations.

The company sunnily predicts that Solein will be cheaper than soy protein within five years. Prices vary, but one recent bulk wholesale price for soy powder is $600 for an order of 2 metric tons, or $3.33 per kilogram. Solar Foods' projection depends on, among other things, the continuing fall in the price of renewable electricity used to generate the hydrogen feedstock from electrolyzing water. The U.S. Department of Energy recently projected that commercial-scale solar PV power will drop from $0.11 now to $0.03 per kilowatt-hour by 2030. Electrolysis uses about 51 kilowatt-hours to generate a kilogram of hydrogen, implying a price of around $1.50 per kilogram. (Another analysis suggests that this hydrogen price milestone won't be achieved until after 2040.) Of course, any source of electricity could be used, but Solein's claimed climate benefits would thereby be significantly reduced.

Solar Foods is certainly not the only company aiming to end the age of agriculture by producing scalable food products that are generated rather than grown. Clara Foods, for example, is using sugar and yeast to produce egg proteins and Perfect Day Foods uses genetically enhanced microbes to ferment sugar to produce whey and casein to make animal-free dairy products. Israel-based Aleph Farms is producing slaughter-free steaks by using bioreactors to grow muscle, fat, and blood cells taken from cows.

The market for fish and seafood has not been neglected. Finless Foods is producing fish fillets and steaks by growing fish muscle cells in bioreactors, whereas Good Catch is pursuing the plant-based route to make fish-free tuna, crab cakes, and fish sticks. Unlike Solein, these companies use feedstocks still grown on farms, but nevertheless, the foods they produce use much less land, water, and fertilizer while generating far less greenhouse gases than do foods grown using conventional agriculture.

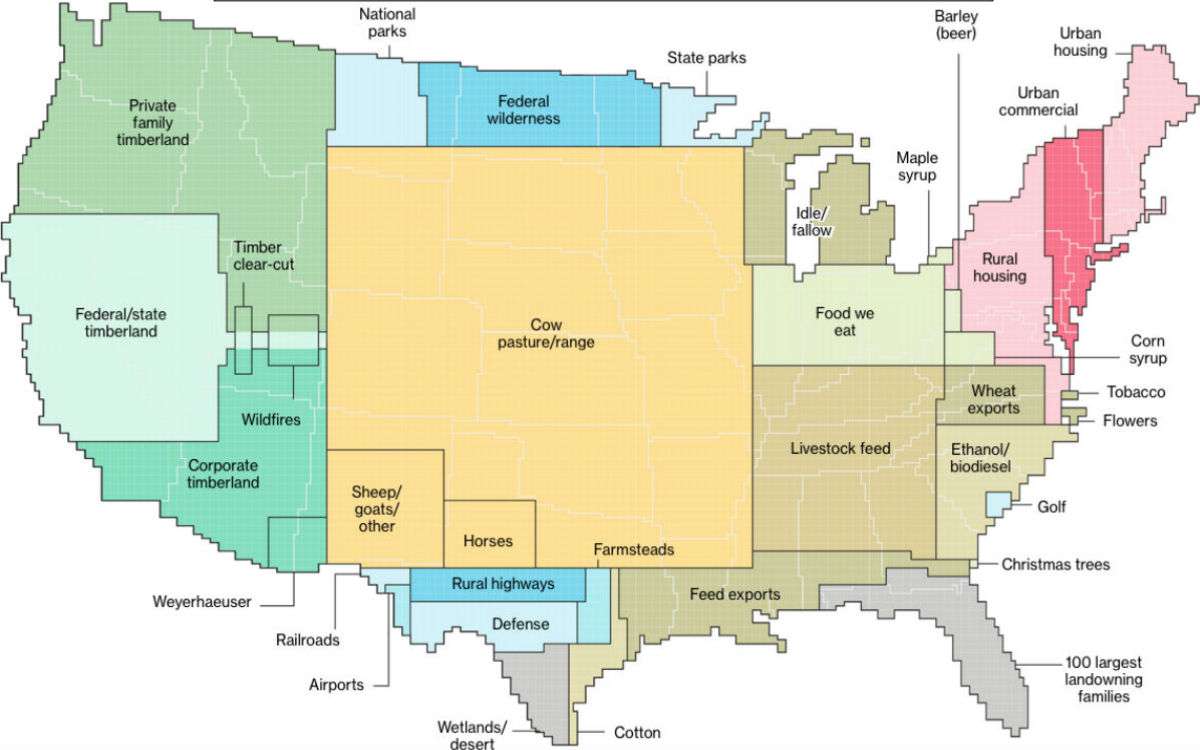

A 2018 study in Science calculated that meat, aquaculture, eggs, and dairy use about 83 percent of the world's farmland while providing only 37 percent of humanity's protein consumption and 18 percent of our calories. This map (below) from a fascinating Bloomberg News article on how we Americans use our land nicely illustrates just how much is devoted to agriculture in the United States.

Notionally speaking, if all meat, milk, egg, and fish production were replaced using generated rather than grown foods that could mean restoring 781 million acres devoted to livestock feed and pasturage to nature. That's about 41 percent of the total land area of the contiguous United States.

Is such a transformation really possible? Not only is this possible, but it is also likely and coming fast, assert the analysts at the independent RethinkX think tank. Their new report, "Rethinking Food and Agriculture 2020-2030,"contends that "we are on the cusp of the fastest, deepest, most consequential disruption of agriculture in history." RethinkX analysts predict nothing less than the collapse of industrial livestock production by 2030 due to being outcompeted by the development and deployment of precision fermentation.

"The cost of proteins will be five times cheaper by 2030 and 10 times cheaper by 2035 than existing animal proteins, before ultimately approaching the cost of sugar," states the report. "They will also be superior in every key attribute—more nutritious, healthier, better tasting, and more convenient, with almost unimaginable variety. This means that, by 2030, modern food products will be higher quality and cost less than half as much to produce as the animal-derived products they replace." They project that modern fermented foods will save the average U.S. family more than $1,200 a year in food costs.

To illustrate just how disruptive ferming will be, the report focuses on cattle production. The analysts project that precision fermentation will, by 2030, reduce the demand for cow products by 70 percent with similar declines for other livestock products. This fall in demand for conventional animal foodstuffs and products will have huge knock-on effects with respect to farm equipment, fertilizer use, livestock feed, and the value of farmland. For example, the demand for soy, corn, and alfalfa as livestock feed will decline by 50 percent by 2030. This disruption will free up hundreds of millions of acres that could be returned to nature while dramatically reducing water consumption, pollution from fertilizer run-off and greenhouse gas emissions. The RethinkX analysts project that the value of U.S. farmland will fall by 40 percent.

Given how conservative most folks tend to be when it comes to the foods they choose to eat, the RethinkX projections for a fast roll-out and adoption of fermented foods will perhaps turn out to be too optimistic. In addition, modern fermented foods will face some stiff headwinds, not least from incumbent farmers who will turn to politicians to help them fend off the competition; the usual claque of anti-technology activists; and, of course, over-cautious regulators.

Nevertheless, the prospect of much lower prices, better nutrition, and substantial environmental benefits all favor eventual consumer acceptance of foods made using precision fermentation.

Show Comments (139)