The 3D Economy

Forget guns, what happens when everyone prints their own shoes?

Last May, Cody Wilson produced an ingeniously brief but nuanced manifesto about individual liberty in the age of the ever-encroaching techno-state-a single shot fired by a plastic pistol fabricated on a leased 3D printer. While Wilson dubbed his gun The Liberator, his interests and concerns are broader than merely protecting the Second Amendment. As Senior Editor Brian Doherty documented in a December reason profile, Wilson is ultimately aiming for the "transcendence of the state." And yet because of the nature of his invention, many observers reacted to his message as reductively as can be: "OMG, guns!"

Local legislators were especially prone to this response. In California, New York, and Washington, D.C., officials all floated proposals to regulate 3D printed guns. In Philadelphia, the city council successfully passed a measure prohibiting their unlicensed manufacture, with a maximum fine of $2,000.

But if armies of Davids really want to transcend the state, there are even stronger weapons at their disposal: toothbrush holders, wall vases, bottle openers, shower caddies, and tape dispensers. All these consumer goods and more you either can or will soon be able to produce using 3D printers.

Imagine what will happen when millions of people start using the tools that produced The Liberator to make, copy, swap, barter, buy, and sell all the quotidian stuff with which they furnish their lives. Rest in peace, Bed, Bath & Beyond. Thanks for all the stuff, Foxconn, but we get our gadgets from Pirate Bay and MEGA now.

Once the retail and manufacturing carnage starts to scale, the government carnage will soon follow. How can it not, when only old people pay sales tax, fewer citizens obtain their incomes from traditional easy-to-tax jobs, and large corporate taxpayers start folding like daily newspapers? Without big business, big government can't function.

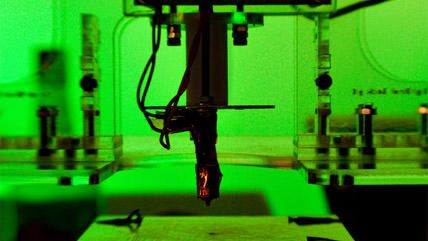

3D printing is a painstaking process, with extruders or lasers methodically building up objects one layer at a time. Most consumer-level devices currently only print in plastic, and only in one color. At online platforms such as Thingiverse.com, where 3D printing enthusiasts share open-source design files and post photos of their wares, the final products often look a little rough around the edges, without the spectacular gloss and streamlining we've come to expect from, say, a Dollar General toilet bowl scrubber.

In many ways, 3D printing barely seems ready to disrupt the monochromatic knick-knacks industry, much less the world. When it takes hours to produce a pencil cup, transcending the state may prove to be a tall order.

And yet in the industrial realm, where 3D printing has been around for decades and goes by the name "additive manufacturing," companies such as Boeing and General Electric are using much more sophisticated machines to produce parts for jet engines. Medical device companies use them to custom-manufacture hearing aids, replacement knees, and designer prosthetics. In time, Cornell University professor Hod Lipson predicts in the 2013 book Fabricated: The New World of 3D Printing (Wiley), 3D printers will be capable of constructing houses with plumbing and wiring in place, and printing "vanity organs" for people who want new or improved athletic abilities.

Inevitably, such technologies and capabilities will trickle down, and probably faster and more radically than many people anticipate. While MakerBot Replicators may still look a little too DIY for those of us who have yet to fully exploit the capacities of our microwave ovens, ease of use is evolving rapidly.

In January, Adobe announced that it is adding 3D printing capabilities to Photoshop, giving users the ability to design three-dimensional objects and send them to their own printers or 3D printers in the cloud. A California startup called AIO Robotics is developing a machine that points the way toward a future where the goods in the picture frame aisle at Target become just as easy to duplicate and manipulate as Metallica's back catalog. It's called Zeus. It looks like an unusually stylish kitchen appliance, and its creators, who met as students at the University of Southern California, describe it as the "world's first 3D copy machine."

Place an object in its central chamber, then push a button. Zeus scans the object in 3D. Push another button, and Zeus uses the 3D file it has created to reproduce an exact plastic replica of your object. In essence, Zeus makes "making" even easier than consuming. If you decide you really, really like the pasta bowl your mom gave you for Christmas, you don't even have to go to the mall, or surf Amazon.com to get another. Just throw it in Zeus and push a button!

In almost all visions of the 3D printed future, manufacturing changes dramatically. If a high-end 3D printer can fabricate a pistol or a panini press on demand, why bother with huge production runs, global distribution networks, warehoused inventories, and the cheap human labor that only under-regulated developing nations can provide? While it will still make sense to produce some goods in large quantities using traditional methods, manufacturing is poised to become a far more local, just-in-time, customized endeavor.

But if the nature of manufacturing is poised to change dramatically, what about the nature of consumption? In many ways, it's even harder to imagine a city of, say, 50,000 without big-box retailers than it is to imagine it without a daily newspaper. So perhaps 3D printing won't alter our old habits that substantially. We'll demand locally made kitchen mops, but we'll still get them at Target. We'll acquire a taste for craft automobile tires, but we'll obtain them from some third party that specializes in their production. Commercial transactions will still occur.

But if history is any guide, more and more of us will soon be engaging in all sorts of other behaviors too. Making our own goods. Sharing, swapping, and engaging in peer-to-peer commerce. Appropriating the ideas and designs of others and applying them to our own ends. Combining resources and collaborating on extremely large and ambitious projects we couldn't hope to accomplish alone. And over time these new behaviors will have consequential impacts on scores of products, companies, and industries.

Already, according to a study authored by Michigan Technological University engineering professor Joshua Pearce and six others, there are significant economic incentives for consumers to pursue 3D printing. According to Pearce's calculations, a person who constructs an open-source 3D printer called the RepRap at a cost of around $575 for parts can theoretically avoid paying between $290 and $1,920 a year to retailers simply by using the device to print 20 common items (iPhone case, shower curtain rings, shoe orthotics, etc.).

If you are willing to invest some time in its construction-Pearce estimates that the RepRap takes around 24 hours to build-the printer can quickly pay for itself, even if you don't use it all that often. If you start making orthotics for your neighbors, who knows, it could even turn into a profit center.

Soon, we'll begin to see the rise of manufacturing Matt Drudges and printer-sharing Reddits. So many different producers will be producing so many different products that it will become harder and harder for even well-established and trusted brands to charge for anything but the scarcest and most coveted goods. In a bid to survive, places like Walmart and Best Buy will begin to offer stuff as a subscription-you'll get 200 lbs. of goods per year for a monthly fee of $19.99.

But maybe even that will seem too steep to you, or just not as autonomous as you'd like. Ultimately, 3D printers and the distributed manufacturing they enable will democratize and mainstream survivalism. You won't need five remote acres, heavy equipment, and a lot of practical know-how to live off the grid. In the realm of your commercial life, at least, you'll be able to DIY in New York City.

Be prepared, however, to expect some pushback from your local regulators. Over the past decade or so, as newer technologies and fewer opportunities for traditional employment have prompted more people to act in entrepreneurially innovative ways, government's response has been the same: Consumers must be protected against strawberry balsamic jam made in home kitchens. Tourists must be protected against immaculately maintained carriage houses that can be rented on a daily basis for below-hotel rates. Travelers must be protected from cheap rides from the airport.

When government realizes that self-produced plastic shower curtain rings are far more potentially disruptive than self-produced plastic pistols, it'll be more than libertarian entrepreneur-iconoclasts at risk.

Editor's Note: As of February 29, 2024, commenting privileges on reason.com posts are limited to Reason Plus subscribers. Past commenters are grandfathered in for a temporary period. Subscribe here to preserve your ability to comment. Your Reason Plus subscription also gives you an ad-free version of reason.com, along with full access to the digital edition and archives of Reason magazine. We request that comments be civil and on-topic. We do not moderate or assume any responsibility for comments, which are owned by the readers who post them. Comments do not represent the views of reason.com or Reason Foundation. We reserve the right to delete any comment and ban commenters for any reason at any time. Comments may only be edited within 5 minutes of posting. Report abuses.

Please to post comments

Nah, they'll just 3-D print their little dictators!

Of all the failed prohibitions and regulations, government attempts to control the software behind the printers will be the most complete failure.

I'm sure there are a couple of critical gun parts that could be blocked from printing at the software level. Photoshop does this with currency. All it takes is a small tech team within the ATF issuing suppression orders to commercial software developers to comply with locking out gun part meshes or be raided and/or shut down. It would be difficult to stop individual developers but these guys are easy enough to track down and assassinate through NSA/FBI efforts. This wouldn't stop every single occurrence but I'm willing to bet governmental efforts won't 'be the most complete failure'.

All it takes is for one team to develop an unlocked 3D printing program and release it onto the net. Once that happens, you can't unrelease something from the Internet.

That would require a hacked prog. Sure, it's workable at the niche underground scale but most people prefer to avoid hacked software on 3-5 thousand dollar machines. And because software requires constant updating many consumers will prefer to stay within the boundaries of their commercially-available (Adobe for example) software just to enjoy the benefits of innovation at the machine level.

You're not thinking big enough. Sure, a 3D printer might be 3-5 grand now, but think about how much demand there will be for them: I bet that by the end (whatever that is), you'll be able to get a 3D printer for the cost of a MacBook Pro, and plenty of people are happy to run cracked, hacked, or pirated software on one of those.

Perhaps. I'm experienced with creating 3D meshes and I own a Replicator 2. Three-dimensional printing has a different learning curve than your standard 2D printing. But, who knows maybe this will all change in a decade.

sooner than that I think. I mean these guys have an incentive to make it as user friendly as possible.

And then the 3d printer will replicate itself....MIND BLOWN!

Not really. You need to be quite bright to assemble a replicated 3D printer.

Apparently you haven't been paying attention to open source programs as of late. Libreoffice is just as good as Microsoft in my opinion because of Microsoft's push for subscription based services. A quality open source 3-d printing program will spring up and be on the level of the best out there. Just give it time.

Open source software, don't even bother with commercial.

THIS.

Yea, I can see it now. The average mom and pop using open source software on their 500 buck Best Buy 3D printer. Not.

My son's school was moving over to a 1 laptop per child model and my son's art class was caught up in a tools snafu. Their expensive adobe licenses were late and they were going to do finger painting for 2 weeks until the software was installed.

I burned a class worth of Artist X disks and sent them into school with my son. A bunch of 6th graders and their teacher were using computer tools the next day.

Some open source projects target the ability to just plug in and use. Those are the ones that mom and pop wlll use and likely they will be made by hackers who are sick and tired of getting mom and pop's commercial software to produce what mom and pop want when the filters won't let them.

Newtown massacre was approx. 1 shot every 2 seconds. State of the art for Civil War era technology but they're sure to ban every black rifle with a vertical foregrip and 10+ rounds regardless of the material it's made of.

Considering metal casting and milling/machining aren't phenomenally more expensive than extrusion technology and the gov't manages to effectively suppress those activities. I agree, I can't imagine that they'll be left with no recourse for preventing plastic printers from making guns.

What? The government doesn't really effectively, proactively prevent the purchasing/building of machining equipment to make guns, do they? I mean, I'm sure there's a bunch of stupid laws requiring licensing of gun manufacturers, but really there's nothing to stop anyone from buying machining equipment, setting it up in a workspace, and just making guns. Heck, with machining equipment, you could easily make certain machining eqipment that's specific to gun manufacture; the die setup that creates rifling shoud be easy to make, from what I understand, and I guess you could make your own shell press. Though making a machine to make bullets or shells would be harder

OK, here's the difference: The average home owner doesn't have much use for metal casting and milling machines. If you have one, you are probably either into guns or cars, or something gear head-ish.

But with the 3D printing tech that is coming down the pike, the average person will have all kinds of uses for a 3D printer. Not everybody needs a specially milled steel part, made to within very tight tolerances, every weekend, although some hobbyist do.

But almost everyone, and definitely every homeowner, needs something from Home Depot every weekend, or some Rubbermaid stuff from Walmart. And when the machine that makes stuff for the second group of people can also produce a gun, it becomes infinitely harder for a government to keep track of.

I mean, how many mills or lathes are there in American garages today? A few hundred thousand? Maybe? When 3D printers become easier to use, they will be counted in the hundred of millions.

what?...

...

OK, but the government doesn't suppress the purchasing of machining equipment or setting up of makerspaces, does it? Like I said I'm sure there's a gun manufacturer's licensing requirement, but it doesn't mean much if someone's determine to make a gun, when there aren't government agents walking around checking everyone's garages for machining equipment and projects being worked on

No, it doesn't. You can buy a mill, drill and lathe setup from Harbor Freight for a couple grand. It's prohibitively expensive for what little use most people would get out of it.

However, once 3d printers are less than about $500, and you'd use it a couple of times weekly, its expense is suddenly justified.

1. For $2-5K, you could do metal casting, welding, and machining in your own garage with the cost of materials being far less than the spools of filament used in these printers. Cody Wilson made his receiver using rented time on a $30K printer.

I don't disagree that the price will come down. I'm just saying that the reason people don't 'print' their own guns (or cars, or light-switches, or orange juice, or popcorn) now is because it's a lot of fucking work and capital to make guns (almost like it's a full-time occupation or something). Saying there will be a 3D printer in every home implies that there's some impetus or market need that only at-home 3D printers can fulfil and I don't see that in any way shape or form. People will have to go to Home Depot(.com) to buy their parts and filament. Home Depot won't go away, if anything, they'll buy into/get bought by house printing companies. That said, why would the ATF go away because people can print their own guns?

2. Makerbot sold to Stratasys for $400M, Oculus sold to Facebook for $2B.

Not only is crafting real shit much less popular than interacting with virtual shit, a 'real big' company like Facebook or Google might be able to tell the ATF 'fuck you' but Stratasys is going to have to hand over lots of addresses and serial numbers when the ATF comes knocking much like Sturm Ruger does now.

Not to say that the government will ever be able to do a good job regulating guns/production, but that they don't really have to. It's dead simple and cheap to produce parts of a gun at home now. Doing it well with zero effort is the hurdle that 3D printing doesn't significantly alter.

3. Not only is it dead simple to produce parts of a gun at home now, it's dead simple to 'deregulate' a gun previously manufactured as well (details about on various parts of the internet, don't ask me for any). The reason it's not done en masse is because people, even the staunchest 2nd Am. advocates, support the level of regulation that exists or are ambivalent.

It's not like we've been living in a 2D economy for the last 10,000 yrs. and manufacturing has been purely centralized and governments exerted their power solely through said centralization. 3D stuff is made amazingly cheaply and effort-free now, discovering and sailing to the New World didn't get the pilgrims away from the oppression of Europe, and the 3D printer isn't magic.

""""and printing "vanity organs" for people who want new or improved athletic abilities."""

Please, please, please, don't let Warty read this!!!!!

"Harvesting their livers in the fall, savin up the kidneys in the fridge, no one ever thanks me when im done, how self absorbed people can be"

""""So many different producers will be producing so many different products that it will become harder and harder for even well-established and trusted brands to charge for anything but the scarcest and most coveted goods."""

They will if they give some value added. Not all 3d or any other manufacturing is the same.

This also applies to today's brands, I buy name brand if it has something I want that others don't supply. However some name brands have undercut their own brand by outsourcing manufacturing to places which also make generic brands and even make them on the same assembly line. If its going to be made the same as the generic brand then why not buy the generic. How many time have we seen recalls on a product cover both name brand and generic since they are actually the same thing.

When they can 3D print a drone to deliver me the 3D pants I just printed out then you might convince me the manufacturing and retail worlds will be turned upside down.

Why do you need a pair of pants you printed to be delivered?

yeah that statement fucked me up too.

how would pants be printed? Cloth has to be woven. You can't print out weaving

You can print pants (even if it makes no sense to deliver pants to yourself that you just printed). Pants don't need to be made of woven cloth, anymore than guns need to be made of steel, or bird-shot made from lead. You are experiencing a blind spot, because for your entire life pants were made from woven cloth. There is even a fancy name for the phenomena, but I can't remember/never knew what it is, and don't feel like searching it out.

Come on, man! Kodak is going the way of the dinosaur because nobody needs film to take pictures anymore, but pants being made without weaving is what makes your brain go into the "does not compute" loop? Have a drink and try again!

lol, what? What the hell are you talking about? Clothes are made from textiles. Textiles are woven.

There's also leather and pleather and PVC, but those are limited. You can't wear those everyday, they don't breathe, they're heavier too. And they're more prone to tearing and can't be tailored/fixed. I have this faux leather jacket that's apparently made of PVC, and it tore pretty easily.

Not to mention that you can't print out those materials in a 3D printer. 3D printing can only make rigid objects. I mean, you could try using the materials they use for those clothes (like PVC) in a 3D printer, but I don't think it would work, it's already such a soft material, if it's made by melting strip by strip together it would never hold together. Plus I think some of them are thermoset materials as opposed to thermoplastics

You aren't thinking far enough into the future, man. 😉 Get out there where it really starts to not matter at all for us on the local time continuum and all sorts of amazing is possible.

(tongue-in-cheek)

yeah, just looked it up, the only fake textiles that aren't woven are plastics with a lot of plasticizer added to make them pliable and move-around-able like clothing.

You couldn't even 3D print those out, since a 3D printer depends on the structure holding its shape as it lowers the platform and builds up the next layer. Pleather would just flop over completely making it impossible for the machine to continue its work.

MAYBE if there were a rack to hold the colthes up, and an entirely differently made machine just for clothes

But still, who the hell wants to wear pleather all the time? You ain't gonna wear no pleather pants

http://www.inda.org/about-nonw.....s/apparel/

none of those textiles are produced in a way that could be replicated by a 3D printer

Well, la-di-da, look at the King of Siam over here with his fancy woven clothing.

I enjoy the enthusiasm of the article but I just don't see 3D printers making the leap into iphone territory any time soon. It's a tech/geek product at best serving a prosumer market consisting of digital creatives, engineers, and inventors. These are the people who don't need their hand held every step of the way which is the exact opposite of products created for mainstream consumers.

Yes, yes, everything starts out small and insignificant and a toy for the rich. Everyone except you understands that basic premise.

Maybe everyone else does. But can everyone else claim to have experience working with 3D meshes and 3D printing technology? Probably not. Fact is, I just see 3D printing as being on a far different learning and usability curve than the ubiquitous two-dimensions which even a grandmother grasps. Perhaps this will change over the coming years.

The only way I see 3D printing become ubiquitous and mainstream is if the tech is obviously cheap (300-600), the filament dual-purpose and very easy to work with, 3D meshes are as commonplace as 2D images, and no alterations are necessary to improve the machine out of the box (which is common with almost all [if not all] affordable prosumer models). All of this of course would be based on what you plan on printing in terms of actual size. Because with 3D printing size does matter.

"Because with 3D printing size does matter."

Nope, plans matter. If I have a printer that can produce components x inches wide, and have plans for a product whose final production step is the snap-together assembly of y number of pieces that are x inches wide, then in theory, I can produce a final product, z, of any arbitrary size, by assembling n number of pieces.

That is level 101 structure creation where load-bearing is largely unimportant.

You mean like computers? Or "networking" two or more computers together? And man, check out those crazy cats who built themselves a horseless carriage.

Computer networks and vehicles were not developed in a vacuum- they were the direct result of scientific progress that centuries.

Now, do I think 3D printing will be mind-blowing in 50-75 years? Sure. Just not within 10 or 20.

I Don't see how 3D printing will lead to the end of effective taxation.

You'll still need to buy the plastic from somewhere unless you're an obsessive recycler. You'll still need to buy the electricity -- unless you have your own power generation system (in which case you pay taxes to buy the materials for it) -- which you'll probably use a lot more of.

Also, assuming the printing saves you money, due to our inflationary currency, you're encouraged to spend rather than save so you'll end up eating out or purchasing frivolities more often and pay taxes that way.

Yeah, in reality, 3D printing will be an immature process until nano-tech becomes mature. Then, any carbon atom will be able to be repurposed... you know what? That is a different technology altogether, and will transform the universe itself, making this planet the origin for the seed technology that will eventually transform every atom in the galaxy into part of a self aware intelligence...

Sorry, got my epochs confused again.

3D printers require extremely cheap plastic feed-stock, and the energy requirements can be more than handled by solar panels and batteries.

I saw these 3-D printers back in the mid-80s at Manufacturing Tool shows. The sales pitch was a proof of concept devise. Make sure the parts will fit together before you invest in tooling and building of the steel parts.

I'm no longer in manufacturing, but I've seen some really good CAD/CAM systems that can indentify any interference issues without even printing the plastic parts. I guess they just repurposed these printers.

That said, I wouldn't mind having one of my own. The grand kids break more things in the house than I can keep track of. It would be cool to put out the plastic parts and stash away the good stuff until they're old enough to appreciate them.

Greg Beato warns that once the retail and manufacturing carnage starts to scale, the government carnage will soon follow.

In other news, Chicken Little says the sky is falling. If only either of them knew what they were talking about.

3-D printing will undo Life's Order as we know it on exactly the same day that we all get our very own flying carpet. Which is sure to happen just as soon as the sky gets done falling (though that may take a while).

In 2006, Cory Doctorow wrote about a future in which radicals use illegal 3D printers to print more 3D printers? http://www.makerbot.com/blog/2.....-printers/

And about that "going off the grid" thing? The gubmint doesn't like that either. Interesting times, indeed.

"Vanity Organs"

Foot long dick, it's nothing but a foot long dick-just say it Greg.

Why would you want a dick that big? Do you really think that most women are going to let you anywhere near their fun parts with that thing? How about an adjustable one, and you could just ask the lady want she wants?

And they say chivalry is dead. I guess adjustable would prolly be better.

Why would you want a dick that big?

Wouldn't that drag in the cold water when you went to the toilet?

my economese is a little shaky as of late, but would 3d printing basically mean a reduction of inputs that translates into increasing returns to scale? I mean they will get better right?

actually thats contradictory...help me!

You are assuming the economy itself doesn't change. At this point, who even has a job? You can't go to work at the sneaker factory. Nobody can. So where does anybody get the money to buy anything in the first place?

When people discuss these topics, and they say things like "the total disruption of the present economic system" they kind of mean "the TOTAL disruption of the present economic system." But don't feel too bad, it is not just economics that can't see what will happen. Politics, religion, morality, mortality, the very nature of reality itself vs. virtual reality, all will be challenged. ALL faiths, creeds, and philosophies will be challenged.

Why the hell do you think it is called the "Singularity?"

I like Ray Kurzweil, and I think he is right in a big picture sense. But sometimes he talks about the singularity as if it's some kind of religious experience. 2045 is the date right? I'll be 65 so I might make it.

Buy a 3D printer and draw your own conclusions.

If he's got a printer then he can print his own conclusions. Which he can decide in advance.

and then he can replicate them.

settle down. It is like any other tech since the beginning of history, and I suspect that Moore's law applies as well. You should read some of Ray Kurzweil's books. He has all these fancy graphs and things. They show that not only does technology get more efficient, but it also gets cheaper and more ubiquitous.

I confess, as I write this at 2:30 AM local time, that I may be slightly too buzzed to discuss economics in a sober manner. I am still sober enough to recommend Ray Kurzweil's books; whether you ultimately agree with his conclusions or not, you will come away with a deeper understanding of the increase in the rate of increase in technological advancement.

Ray Kurzweil is a starry-eyed theorist with a wonderful imagination generating ideas that will likely only benefit people hundreds of years from now. Very useful chap there.

So in this wonderful new economy where you only copy things that often cost millions of dollars and years to develop, who will have the incentive to continue creating and developing so you can rip them off?

Gee, it's really hard asking the obvious questions.

people create out of a sense of purpose as much as out of a sense of profit.

Bullshit.

If millions of people are jacking up copyrighted movies and songs daily what makes you think they'll give a second thought about jacking up 3D products?

Think mixtape except with patented 3D output.

Reason.com is running apache and red hat linux which is a combination that dominates the net. Nobody has ever done anything but fix their own problem and release the patch for apache. That's how it's become the dominant web server on the internet. A vanishingly small percentage of Apache users do this. Why wouldn't shoes work the same way?

in fact, if this takes off, there will be huge increases in productivity that will result in more leisure. The human race is creative, in fact creativity may very well be what it means to be human. So I don't think it's going anywhere.

a lot of overblown noise. Like the douchebags who claim we'l be able to download our brain onto computers within 30 years (hint, we won't, the human brain is almost infinitely complex and contains more switches than all the computers in the world put together)

How would 3d printing be feasible to replace everything? I mean, how fast can you imagine a 3d printer can print? Even the fastest armature movements would still translate into a slow production process compared to the stamped-out process that so many of the simple consumer goods this guys is talking about are made with. Plus the heating-cooling process puts time limits. The armature has to wait for the melted plastic to cool.

I mean, most of what your paying for is shelf space/distribution with a lot of these things, not manufacturing.

And let's not forget that these pieces are almost never as resilient as clasically-manufactured products. Stuff thats melted together dot by dot is always going to be like "spongy" if you will.

And who are these people who talk about 3d printed houses? Do they have any idea how a house is built? How the hell are you going to print out wires and plumbing along with the house? And who the hell says you need a new manufacturing process for houses, or that THAT'S the reason housing is so expensive? Traditional frame Houses are already very well suited to mass production, and are frequently made in such a way in modular home factories. Technically you could even automate a lot of that process, but even with the price of American workers it's easier and cost effective to just have guys lay out the studs on the table.

You are obviously very familiar with 3D printing tech. I concur with your post. There is so much marketing hype within the 3D printing world that it tends to obscure the realities, a few you mention here.

what? Are you being sarcastic?

I'm not super familiar with 3D tech, I'll admit. The claims of them eventually making everything at centralized locations (home, some store) seem stupid to me.

I AM however very familiar with construction and I can tell you I DEFINITELY know what I'm talking about with house manufacturing. Imagining 3D printed houses ignores that you'd have to maintain such a huge complex machine, as it would inevitably break relatively often. The old-fashioned form of mass-produced housing will remain the best method in the forseeable future; tables with rollers, guides to help position the studs exactly, tools to help lift and carry the stud walls hither and thither, and elevated platforms to help the installers get up there and put shit in. Then trucking to the site, or the facility is on-site. Heck, you could build the studwalls and just bring those over to the house site if your facility is on the subdivision.

Look up the history of Levittown, NY. They have had mass-produced houses for a LONG time.

*the claims.... just seem stupid to me.

Oh bullshit. I can build a house from pad to roof, possessing, in fact, a contractor's licence. There is no reason that a sufficiently intelligent machine could not print out parts for a modular system that is better than anything I could spend thousands of dollars and hundreds of hours developing; running it past a architectural firm to get city approval.

Just because YOU can't imagine it doesn't slow me down one minute.

OK... how? I'm not unwilling to hear anything on the subject. I just don't seriously see how.

How you gonna do wires? You can't print a wire. I googled it and best they said was there would be modular blocks containing wires in them. But then you'd need an whole extra armature on the machine that amounts to an entirely different machine just to pick up and stack blocks. And then how would you make sure the wires are tied together sufficiently? They could have plugs I guess, but it doesn't sound very trustworthy, what if some don't align right?

How about plumbing? Remember, both drainage and supply has to be watertight, and out of appropriate materials

It just doesn't seem feasible, at least not as a cheaper or faster alternative than traditional forms of mass-produced housing

The only advantage I could glean from the videos I watched is that the 3D printer can more easily splooge out non-rectilinear (i.e. dome and dome-like) concrete buildings, which apparently are better at withstanding earthquakes, so you could have concrete homes in earthquake areas. Indeed the printer would be better at that one thing, not needing to do the awkward job of lining and leveling for curvy shapes.

But that's it

I think you can print metals. If not, you could definitely have the wires inlaid into the material during the printing process, or at worst, have the conduit incorporated into the design. Water-tight connections would not be difficult. I mean, I'm still allowed to use glue during assembly right?

As far as making things line up, that's kind of a big part of construction anyways.

What? Is this house printer going to splooge out concrete or metals? Because those are two very different machines. And how would conduits be incorporated? There would have to be a whole separate armature just for that. And how would the concrete splooger do its thing with a conduit in the way now? And how do you deal with the wall penetration for it?

You end up with a huge rube goldberg like machine

//water-tight connections would not be difficult. I mean, I'm still allowed to use glue during assembly right?

What? Yes they would. You think a bunch of junctures in a bunch of blocks are going to be watertight just because you used glue? Not to mention now you've added a glue-splooging armature on top of the already extra block-layer. Again, rube goldberg machine

And what assembly? Are you saying that there are going to be people on the site doing work on the house? Because then you've defeated your entire premise.

//As far as making things line up, that's kind of a big part of construction anyways.

What? did you read what I said? Which thing are you referring to? I said the printer is BETTER at non-rectilinear house building, which I conceded is it's one advantage, as it wouldn't need to do the weird levelling and lines that would come with humans trying to do spherical masonry shapes

The Israelis have already designed a platform 3D printer that prints in concrete and have it at a size that can print whole house sized parts that are bolted together to make a house.

Imagination is fine until it hits the wall of reality. And what you are imagining will require several decades if not a century of innovation.

Most of the 3D printing fanboys don't live in reality. They seem to also think the specially prepared printing materials just magically appear out of thin air for free.

Dude, are you arguing for or against modular buildings? LOL It seems to me pretty easy to design a building template where you have a core, then certain modules that branch off from there, with the corresponding utilities connections.

Did you read past the first sentence?

Imagine what will happen when millions of people start using the tools that produced The Liberator to make, copy, swap, barter, buy, and sell all the quotidian stuff with which they furnish their lives.

Yeah, and bring your bong and your booze, because this isn't ever going to happen in reality.

Printing plastic is one thing. But occassionally we need other materials, like metals and ceramics.

A "printer" that can just pop out SAE grade bolts for your car is not something you're going to have in your garage. At least not within the next century. GE might be able to do it, but that's a far cry from a motivated home hobbyist. Which is further still from a home user that knows nothing about materials science.

Go take a serious look at what's required to produce quality metal alloys, and quality ceramics. Hint: think "wow mom, those are some very high temperatures", and you'll also need controlled gas atmosoheres which might be just slightly poisonous. And btw you're going to need some kick-ass gas and electric hook-ups to run this kind of equipment.

Mini steel and titanium mills in your own garage? You're dreaming. Getting these printers beyond plastics in the home user market is a long, long way off. If ever.

Again, old school eyeballs! Why can't plastics take the part of metal in designing new parts? Because old people who will be dead in 20 years don't believe that the plastic part is as good. Wow, that's a good argument against the technology of the year 2014!

//Why can't plastics take the part of metal in designing new parts?

Because metal is metal and plastic is plastic?

Are you seriously comparing the mechanical, temperature, and chemical properties of plastics and metals? You do realize metal is the only material that can have the shit seriously beaten out of it, and also get really hot, and doesn't fail, and even when it does fail, it may merely bend, not crack?

Yeah, plastics aren't like that. You aren't going to be seeing plastic bolts holding down engine blocks anytime soon... Or even being bike parts, or even office equipment

OK I phrased that wrong. I admit that for the foreseeable future you are not going to be producing plastic bolts with the same sheer strength, etc. But what I meant is the redesign of the object in the first place. For instance, if my car has a plastic body instead of a steel one, I don't need steel bolts, for the body; I need glue. Sure, there is still the frame, suspension, etc, but just because things have always been done one way doesn't mean they can't be done differently.

They have plastic car bodies. Fiberglass and plastic. They been doing that for years.

But again, you can't print those out if they're to have the requisite resilience. Even if you could, why whould you? when once you have the car plans and the exact dimensions you need, you can just make one big mold for a heating press that stamps the panels out from plastic blanks, like is done now. The stamping out is much faster than the 3D printing. Granted, for each model you need to create a new blank, whereas a 3D printer you've already bought, but it's an extremely minor cost savings compared to the much greater speed of stamping things out

You keep pointing to normal everyday things and proposing that they be 3D printed. Dude, just accept it, 3D printing has a few advantages for a few types of things, not every damn thing.

Sorry, but some of the 3D printers do print in metal, sintered with a laser. Ceramics - well they can print the unfired clay and then you have to bake it. They've been doing that for years.

3D printing is not new. It has been around for almost 40 years. There has been a lot of development to get practical machines down to desktop size.

Place an object in its central chamber, then push a button. Zeus scans the object in 3D. Push another button, and Zeus uses the 3D file it has created to reproduce an exact plastic replica of your object.

My oh my, isn't that wonderful? Now, my child, show me that you can do this with an electric motor. Or a garden tractor. Or a car battery. Or....any number of other things that civilization more or less depends on.

In almost all visions of the 3D printed future, manufacturing changes dramatically.

For those who brought their bong and their booze, I'm quite sure that's true.

Give me a 3D Plastic printer, and I bet I could give you an acceptable rechargeable lawn mower, that weighed in at 5 pounds, in what? maybe 2 years research?

Which would break apart as soon as it hit a rock... or you accidentally dropped one side of it on the sidewalk while checking it, or what have you. At the very least the blade and motor MUST be metal, which negates the 3D printer claims. Maybe the metal parts could be printed, but from what I;ve seen you need to use titanium in the printer to get a resilient part*, which is way way more expensive than steel, eliminating any savings

*remember, aditive manufacturing by its very nature makes a weaker part. A bunch of dots sintered together is like a facy styrofoam almost, as a perhaps weird analogy. You can't compare it to parts milled from COMPLETELY solid ingots/bars/ whathaveyou and THEN heat treated for extra hardness

Why does the blade have to be metal? The have been using plastic blades and nylon cutting line for years now. And while an internal combustion engine made of plastic is a bit unrealistic, I don't think it would be that hard to design a plastic electrical motor.

"I don't think it would be that hard to design a plastic electrical motor."

A rechargeable motor to boot.

Anyone with significant 3D skills with a knack for engineering and research can print what appears to be something that can cut grass.

Assuming it even starts, your printed lawn mower might last 3 seconds during the grass cutting phase but not before your plastic rechargeable motor would disintegrate due to heat, mechanical forces, and friction issues. I suppose you could just wait a century to try again.

yeah, right. YOU feel free to cut your grass with a plastic blade. See how well that turns out.

a plastic electric motor would just have a plastic housing. The wires would still have to be metal and you'd have to buy the premade magnet

Someone is already working on an open source 3D printer than uses carbon fiber roving rather than plastic bits. Spin it out based on the design, then pop the whole thing in your oven to harden. If its good enough for a fighter jet I think it will suffice for a housing on a lawn mower.

Truly laughable.

Libreoffice is just as good as Microsoft in my opinion because of Microsoft's push for subscription based services.

OpenOffice. It's free. Works great. Reads and writes word and excel files and other formats.

In Philadelphia, the city council successfully passed a measure

Is there a redundant word in this sentence, or is it possible to pass a measure unsuccessfully? If successful means it had the intended effect, isn't it too early to say?

Imagine the complete and utter destruction of the Chinese economy if 3D printing becomes commonplace.

It won't happen overnight, but face it- machines are going to eliminate a lot of jobs and society is going to change as a result. Hopefully in a good and positive way.

We look back on conscript armies and ask how nations depended on unwiliing soldiers-perhaps 100 years from now people will wonder how we depended on "unwilling" workers.

I get mail from the Motley Fool every few weeks inviting me to imagine that very phenomenon.

We've always had a tug of war going between products and services, so there's nothing really new here, except that lately services, bankrolled by a tidal wave of easy money, have been winning. But to answer the question, ppl will fight over raw materials.

Governments already can't handle the few electric cars that are on the road. They're already screaming about lost revenue from gasoline taxes! That's why whenever the Government tries to get me to change my habits (always for the greater good that I'm too myopic to understand without their hand shoved up my ass) I push back.

I agree, I can't imagine that they'll be left with no recourse for preventing plastic printers from making guns.

Living in a world of 3D is so cool.

From your lips to God's ears, my friend.

As always there are hits and misses about the future of 3D print. It was good to see Rep-Rap mentioned. In all the commerical hoopla its sometimes get missed the open source side of things. But alot of article has some obstacles --

* Filament costs can be higher than the traditional costs of a legacy good. Say like a shoe.

* Energy costs can be higher.

* The tech really needs to advance to the point of a multi-nozzle print head like what is in current inkjet tech. It will up the speed greatly. Single nozzle printers can take hours to assemble a product.

* Cost. For a household that only needs a couple of something 3D print will be useful. But industry typically needs thouands of the same widget. That is where injection molding comes in. Fact IM can now be ordered online in units of less than a thousand at very competitive prices. Fact the irony is, one enterprising fellow has actually taken the pieces of Rep-Rap and contracted a chinese firm to run off a thousand units of plastic bits. It was cheaper than doing it on the boot strap rep-rap.

The political aspects won't be realized in some ways. What the author failed to take into account is governments themselves using 3D to enhance their influence in making anything that they might need. So in the respect this tech is a two edged sword.

Long live 3D.

There will come a time when designers will simply design for the love of designing - and the ego boost of walking down the street and seeing everyone wearing a Joe Blow jacket (the name will be somewhere in the design).

want to transcend the state, there are even stronger weapons