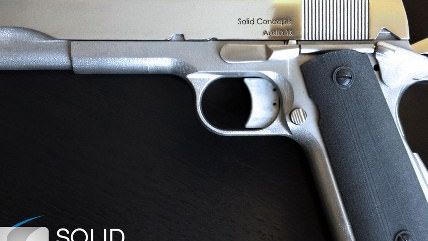

First 3D-Printed Metal Gun! That Addresses Politicians' Detectability Worries, Right?

Just months after the first 3D-printed gun appeared in un-lovely but very workable plastic, Solid Concepts, an engineering firm that specialized in rapid prototyping and custom manufacturing, says it 3D-printed a gun in 17-4 Stainless Steel and Inconel 625 (a nickel-chromium alloy). Politicians have fretted since Cody Wilson and Defense Distributed unveiled the first 3D-printed gun that plastic pistols raised concerns about DIY undetectable firearms. Do you think the Solid Concepts announcement will allay their concerns and set them to worrying over something else? Hmmm…

On the company blog, Solid Concepts' Alyssa Parkinson notes:

Solid Concepts is a world leader of 3D Printing services, and our ability to 3D Print the world's first metal gun solidifies our standing. The gun is a classic 1911, a model that is at once timeless and public domain. It functions beautifully: Our resident gun expert has fired 50 successful rounds and hit a few bull's eyes at over 30 yards. The gun is composed of 30+ 3D Printed components with 17-4 Stainless Steel and Inconel 625 materials. We completed it with a Selective Laser Sintered (SLS) 3D Printed hand grip, because we're kind of crazy about 3D Printing.

I like the combination of old-school 1911 (a model of gun I enjoy shooting) and new technology, although the century-plus old design also enabled the company to fashion something that went bang in a time-proven way without treading on anybody's intellectual property rights. Interestingly, the barrel rifling was printed right into the gun, not machined. In fact, no machining was used, although there was some hand finishing on the final product.

For Solid Concepts, a California-based firm with offices in Arizona, Texas, and Michigan, (the gun was printed in Texas) the 3D-printed gun, more than anything else, was an attention-grabbing way of demonstrating the company's ability to use new technology to construct tough and durable products. As Parkinson points out, this feat isn't likely to be replicated in the home workshop anytime soon. "The industrial printer we used costs more than my college tuition (and I went to a private university) and the engineers who run our machines are top of the line; they are experts who know what they're doing and understand 3D Printing better than anyone in this business."

But new technology has a way of coming down in price as it matures and spreads—a phenomenon that can only be encouraged when laser-sintering patents expire in a few months. That won't necessarily put laser-sintering printers within range of your budget in the short term, but it's certainly a step in that direction.

Somehow, I don't see Sen. Charles Schumer, Rep. Steve Israel, and the other politicians who have been publicly rending their garments over plastic guns being entirely satisfied by this development.

Show Comments (171)